The difference between busbar and busway

The difference between the two is that busbars do not have an enclosure, and busways have a protective enclosure.

What is the difference between busbar and busway?

In this guide, you’ll learn:

What is a busbar?

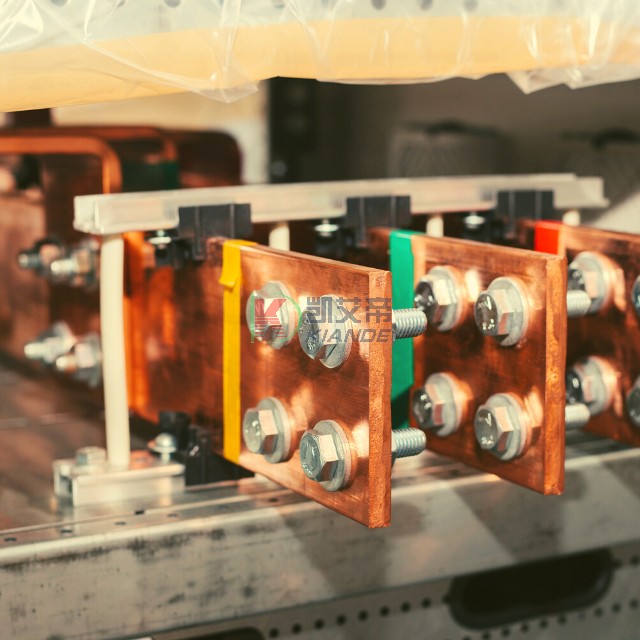

The connection of voltage distribution devices at all levels in the substation and the connection of electrical equipment such as transformers and corresponding distribution devices are mostly made using bare wires or strands of rectangular or circular cross-section, which are collectively referred to as busbars. The role of busbars is to collect, distribute and transmit electrical energy. As the busbar is in operation, there is a considerable amount of electrical power passing through. In the event of a short circuit, it is subjected to great heat and electrodynamic effects. Therefore, what must reasonably select the busbar material, cross-sectional shape, and cross-sectional area to meet the requirements of safe and economical operation.

Busbars are divided into hard busbars and soft busbars according to their structure. Hard busbars are separated into rectangular busbars and tubular busbars.

Rectangular busbars are generally used in the main transformer to the distribution room. The advantages are easy construction and installation, small changes in operation, and large load capacity, but the cost is higher.

The soft busbar is used outdoors, as the space is ample and the conductor does not swing enough to cause the distance between the lines. The soft busbar is easy to construct and cheap to build.

What is a busway?

The busbar system is an efficient current transmission distribution device, specially adapted to the needs of higher and higher buildings and large-scale factories for economic and rational wiring.

With the emergence of modern engineering facilities and equipment, the rapid increase in electricity consumption in all walks of life, especially the emergence of numerous high-rise buildings and large plant workshops, the traditional cable as a transmission conductor in the current transmission system can no longer meet the requirements, the parallel use of multiple threads to the site installation and construction connection has brought a lot of inconveniences.

Busbar trough as a new type of power distribution conductor came into being, compared with the traditional cable, fully reflects its superiority in high current transmission, at the same time, due to the use of new technology, new technology, dramatically reduces the busbar trough two end connections and the contact resistance and temperature rise at the tap port plug, and the use of high-quality insulation materials in the busbar trough, thus improving the safety and reliability of the busbar trough, making the whole system more perfection. The structure of the busbars is described as follows:

Insulation support: an integral part of busbar equipment, used to support the conductors in the busbar equipment.

Mounting plate: A plate used to support various elements and suitable for installation in a plant.

Mounting frame: A frame used to support various components and suitable for installation in a plant.

Housing: A component that protects the equipment from certain external elements and keeps the equipment from being directly accessible in all directions, with a protection class of at least IP30.

Door: A hinged or sliding overlay.

Cover: The upper and lower shell surface of an enclosure is usually a component of busbar equipment used to cover openings in the section. It is fixed with screws or similar and is generally not removed after the equipment has been put into operation.

Side panels are the left and right sides of the housing; usually, a component of the busbar equipment is used to cover the openings in the housing. It is fixed with screws or similar and is not customarily dismantled after the equipment has been put into operation.

Insulating partition: a component used to protect against direct contact from all directions at the entrance and against arcing from switchgear and similar devices.

Electrically charged parts: Conductors or conductive parts used for energizing in everyday use, including neutral conductors, but excluding neutral protective conductors.

Exposed Conductive Part: An accessible conductive part of electrical equipment which is not customarily energized but may be energized in the event of a fault.

Protective conductor: A conductor that is electrically connected to the following components to prevent the risk of electric shock.

Special reminder: the cable is by the cross-section to say, busbar is following the rated working current to say (generally said 400A busbar) the same 400A domestic products cross-section 240mm, some only 180mm. The difference is too big, so there are some 1.4 yuan/amp x meters, 2.0 yuan/amp x meters, higher. It is recommended to ask the manufacturer to provide insulation instructions and marked busbar specifications to avoid being fooled.

Busbar applications

Busbar has a series of compact structures, high insulation strength, high transmission current, good interchangeability, stable electrical performance, easy installation and maintenance, and a long lifetime. It is widely used in industrial and mining enterprises, high-rise buildings and public facilities, etc., for power supply and distribution systems.

Busbar characteristics

1.Expandability: For busbar, what can do system expansion by adding or changing several segments with a high re-utilization rate. In most cases, we cannot reuse the cables because the lengths and routes are different. To extend the system, we have to buy new threads to replace the old ones.

2.Line optimization: Using busbars, we can merge specific branch circuits and transform them into one large busbar with plug-in boxes. It simplifies the electrical system and gives a lower current value than with more strands. The cost of the project is therefore saved, and it is easy to maintain. For traditional cable lines, cables can make the electrical system extremely complex, vast, and challenging to maintain, thus wasting project costs and installation space.

3.Safety: the metal-enclosed shell of the busbar can protect the busbar from mechanical damage or animal injury, the installation of the insertion unit in the distribution system is very safe, the shell can be grounded as a whole, the grounding is very reliable, while the PVC shell of the cable is vulnerable to mechanical and animal damage, the installation of the line must first cut off the power supply, if there is an error occurs will be very dangerous, especially the cable to carry out on-site grounding work The unreliability of the grounding leads to increased danger.

4.performance: bus bar using copper or aluminum row, its current density, small resistance, small skin effect, no need to reduce the capacity to employ. A small voltage drop also means slight energy loss, ultimately saving the user's investment. As the cable core is a multi-stranded fine copper wire, its root area is larger than the busbar of the same current level. And its "skin effect" is profound, reducing the current rating, increasing the voltage drop, and making it easy to heat up. The energy loss of the line is high, and it is accessible to age.

5.Plug-in switch box: what can use plug-in switch box with air type busbar trough. No additional accessories are needed for installation. Plugging feet is the most crucial part. It is made of copper alloy stamping, heat treatment to enhance elasticity, and surface tin plating treatment. Even if plugged more than 200 times, it can still maintain a stable contact capacity. The box is set up with a grounding point to ensure reliable grounding, and the box is set up with a switch circuit, using plastic case circuit breakers to tap the line's capacity for overload and short circuit protection.

6.installation: busbar consists of many sections, each short and light in length. Therefore, the structure can be completed quickly with only a few people. The busbar is available in many standard parts and from stock to be shipped promptly and save work time on site. Its tight "sandwich" construction reduces electrical space, thus freeing up more commercial use, such as rental or as a public space. For the installation of cables, this is a difficult task. Because the individual wires are often heavy, the installation work requires the collaboration of many people and takes a lot of time to complete. Also, the bending radius of the cable requires more installation space.

We are a professional manufacturer of Busbar fabracation machine in China with low price and good quality. Contact us for your customized purchasing solution.

Want to know more about the product

Suzhou Kiande Electric Co.,Ltd.

Tel:+86 512 62994177

Phone:+86 18115561910

Fax:+86 512 62764177

E-mail:cy@busabrequipment.com

Skype:yi_tina1

WhatsApp:+8615962150889

Add:No. 123 Suzhou Dadao East Road, SIP, Suzhou City, Jiangsu Province, China