Suzhou Kiande Electric Co.,Ltd.

OUR PRODUCTS

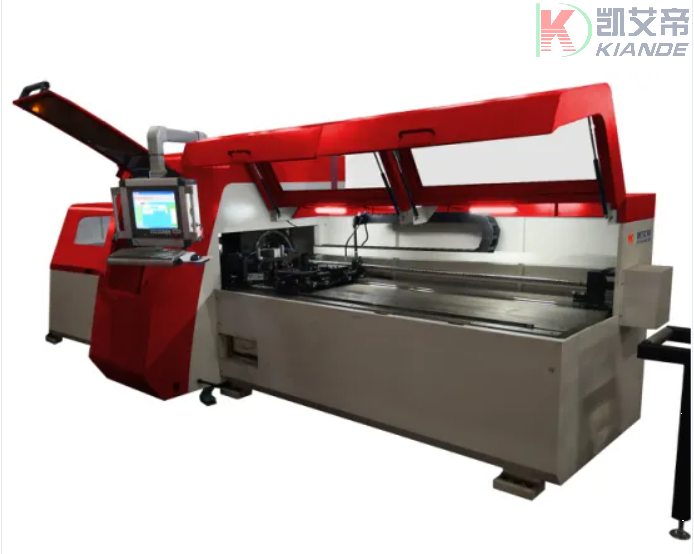

CNC Busbar Bending Punching Shearing Machine

CNC busbar bending punching shearing machine can realize automatic bending of two ends

Contact us

CNC Punching and Bending machine

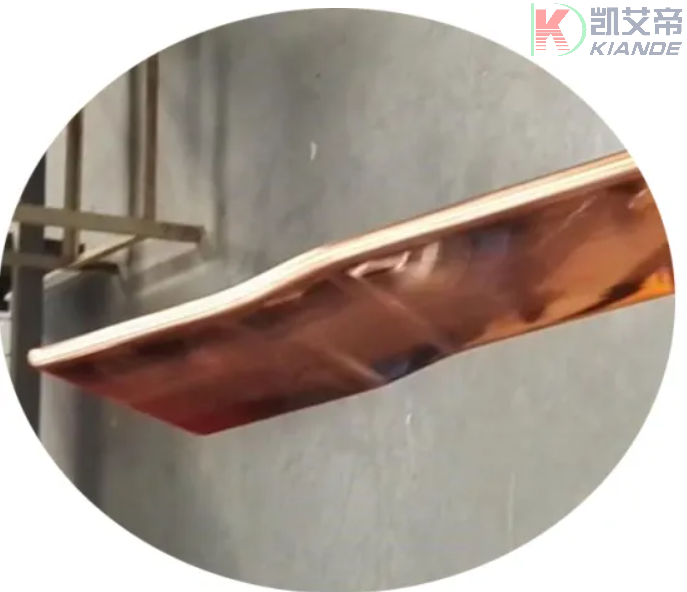

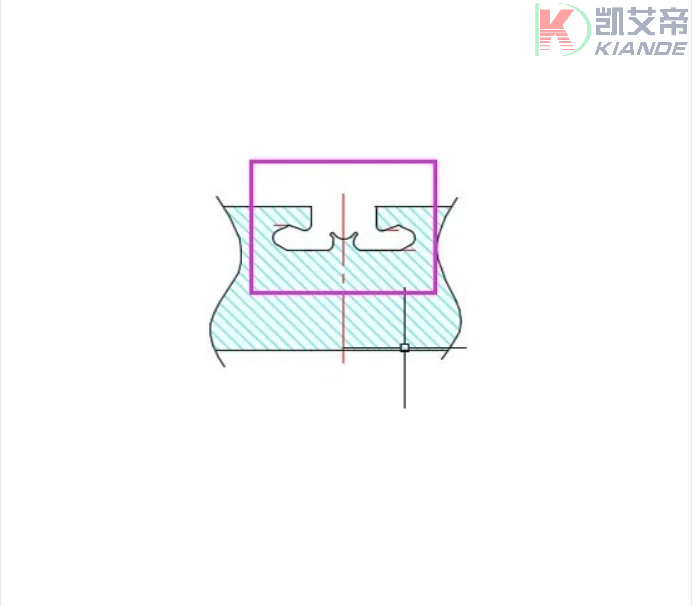

Cnc Busbar Bending Punching Shearing Machine can realize automatic bending of two ends, as well as automatic opening mouth and pressing of piler through inputting required length, width and piler position in the PLC control system.

Cnc Punching And Bending Machine & Cnc Busbar Machine & Details

Automatic CNC busbar punching cutting bending machine

By busbar conductor multifunctional processing machine, operator will input values such as length, width, piler position, quantity and etc. to initiate automatic working procedures including ends punching, piler opening, piler punching and etc..

Advantages:

It can process the bus bar longer than 1meter completely automatically. The working efficiency is very high, around 1 minute per piece.

Disadvantages:

The very short bus bar cannot be processed on this machine.

Advantages:

It can process the bus bar longer than 1meter completely automatically. The working efficiency is very high, around 1 minute per piece.

Disadvantages:

The very short bus bar cannot be processed on this machine.

Multifunctional bus bar processing machine

The machine can complete various processing techniques of punching hols(round holes, long round holes etc), embossing, cutting, slotting, cutting round corners etc.

The machine can automatically process copper with 3mm thickness and 15mm width.

The hydraulic main and assistant double clamp and the clamp can automatically change. That can provide the machining precision and work efficiency.

Automatic draging(push material) system can push off the finished workpieces.

Large die library, cutting surface is smooth without indentation. Die material is high performance alloy steel mold, quenching process is advanced, the processing level is high and long service life.

Why choose us —FAQ

Related suggestion

Want to know more about the product

Suzhou Kiande Electric Co.,Ltd.

Tel:+86 512 62994177

Phone:+86 18115561910

Fax:+86 512 62764177

E-mail:cy@busabrequipment.com

Skype:yi_tina1

WhatsApp:+8615962150889

Add:No. 123 Suzhou Dadao East Road, SIP, Suzhou City, Jiangsu Province, China